ABOUT

BioMCat focuses on the valorization of lignin-rich co-products, namely Brewers’ Spent Grain (BSG) from breweries and lignin extracted from black liquor or wood bark from paper industries. The objective is to develop a novel process for the transformation of lignin rich biomass to aromatic aldehydes as value-added chemicals.

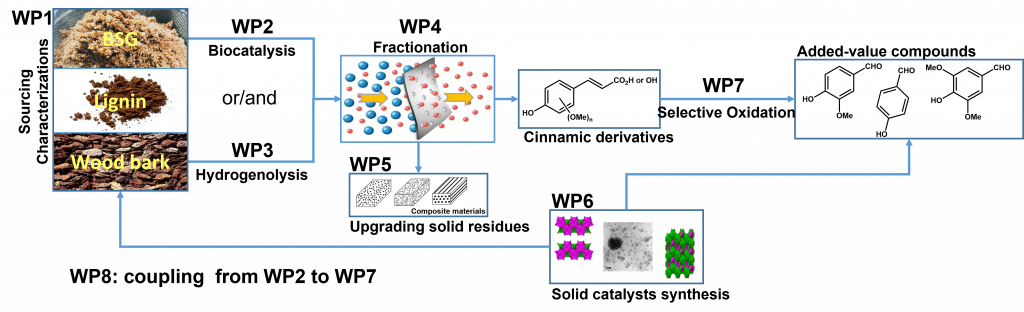

For this, the project will focus on a first step of selective depolymerization of lignin toward cinnamic derivatives which will be carried out by biocatalysis and hydrogenolysis. After a separation step by membrane filtration, the cinnamic compounds will be selectively oxidized toward the target compounds, such as vanillin. This later reaction will be conducted under mild conditions (oxygen atmosphere in aqueous media) using heterogeneous supported metal catalysts or stabilized metal nanoparticles. BioMCat units together partners from different fields, bringing their complementary expertise to the project.

To reach the objectives, the project is divided in eight work-packages (WP). WP1 focuses on sourcing the lignin rich substrates from breweries and paper mill industries. Lignin extraction from these resources will be operated using robust methodologies developed by FCBA partner. WP2 will study lignin depolymerization using enzymatic biocatalysts or fungi, and is led by renowned experts in the field from INRAE-BBF, while WP3, led by IRCELYON, consists in developing selective lignin depolymerization to cinnamic compounds though hydrogenolysis. Cinnamic derivatives contained in the complex mixtures obtained from WP2 and WP3 will be then purified using a global fractionation approach through membrane filtration (WP4), thank to expertise of IPHC partner. Following this separation step, IFPEN and IRCELYON partner will evaluate the selective oxidation of cinnamic derivatives to aromatic aldehydes (WP7), using catalysts prepared by these partners (WP6). One of the objectives of this project will be the development of new solids catalysts (WP6) selective for hydrogenolysis (WP3) and oxidation (WP7) reactions. Finally, we plan to evaluate an integrated process combining all the steps mentioned previously (WP8), starting by simulating the operating plant. An additional WP5 is planned to further valorize the solid residues obtained from WP4 by making sustainable composites. Thus, the different solid and liquid fractions obtained from lignin will be used and exploited in this process.

BioMCat proposes in an original way a two-step process which couples biocatalyst & chemocatalyst by cascade reactions thanks to an intermediate membrane filtration step. By reaching its goals, BioMCat aims at providing new routes for upgrading lignin contained in the co-products of breweries and paper mill industries, thus increasing the economic balance of these industries by providing, alongside their main target products, added-value aromatics for fine chemistry applications.

This interdisciplinary project will be possible thanks to a varied consortium bringing together experts in heterogeneous catalysis (IRCELYON, IFPEN), biocatalysis (FFB) and separation processes (IPHC).

Please visit BioMCat on the website of the PEPR program.

This work is supported by a government grant managed by the Agence Nationale de la Recherche under the France 2030 program, with reference ANR-24-PEBB-0002.